Understanding Air Conditioner Parts: A Comprehensive Guide for Pilots

Air conditioners are essential components of modern aircraft, providing a comfortable and controlled environment for pilots and passengers. To ensure the efficient and reliable operation of air conditioners, pilots must have a thorough understanding of their parts and functions. This comprehensive guide will delve into the various components of air conditioners, their significance, and the importance of proper maintenance and troubleshooting.

Overview Of Air Conditioner Parts

Air conditioners consist of several key parts that work together to regulate temperature and humidity within the aircraft cabin. These parts include:

- Air Compressor: The air compressor is the heart of the air conditioning system, responsible for compressing and circulating refrigerant.

- Condenser: The condenser dissipates heat from the refrigerant, converting it from a high-pressure gas to a high-pressure liquid.

- Expansion Valve: The expansion valve controls the flow of refrigerant into the evaporator, regulating the amount of cooling provided.

- Evaporator: The evaporator absorbs heat from the cabin air, converting the refrigerant from a low-pressure liquid to a low-pressure gas.

- Blower: The blower circulates the cooled air throughout the cabin, distributing it to various vents.

- Controls: The controls allow pilots to adjust the temperature and fan speed, customizing the cabin environment.

Types Of Air Conditioner Parts

Air conditioners comprise various types of parts, each serving a specific function. These parts can be categorized into four main groups:

Air Compressor Parts

- Compressor Head: The compressor head houses the piston and cylinder, where the refrigerant is compressed.

- Connecting Rod: The connecting rod connects the piston to the crankshaft, transmitting power from the motor to the compressor.

- Valves: Valves control the flow of refrigerant into and out of the compressor.

- Air Filter: The air filter prevents dirt and debris from entering the compressor.

- Pressure Gauge: The pressure gauge monitors the refrigerant pressure within the system.

Air Filter Parts

- Filter Media: The filter media traps dust, pollen, and other airborne particles.

- Filter Frame: The filter frame supports the filter media and provides a housing for the filter.

- Gasket: The gasket seals the filter frame to prevent air leakage.

- Mounting Bracket: The mounting bracket secures the filter to the air conditioning unit.

Air Regulator Parts

- Pressure Regulator: The pressure regulator controls the pressure of the refrigerant within the system.

- Pressure Gauge: The pressure gauge monitors the refrigerant pressure within the system.

- Solenoids: Solenoids control the flow of refrigerant through the system.

- Transducer: The transducer converts pressure signals into electrical signals, which are then processed by the control system.

Air Motor Parts

- Air Motor Housing: The air motor housing contains the rotor and stator.

- Rotor: The rotor is the rotating part of the air motor, which is driven by compressed air.

- Stator: The stator is the stationary part of the air motor, which contains the windings that generate the magnetic field.

- Air Inlet: The air inlet allows compressed air to enter the air motor.

- Air Outlet: The air outlet allows the expanded air to exit the air motor.

Common Materials Used In Air Conditioner Parts

Air conditioner parts are typically made from various materials, each with unique properties and advantages. These materials include:

Metal Alloys

- Durability: Metal alloys are known for their strength and durability, making them suitable for components that experience high stress and wear.

- High Tensile: Metal alloys have high tensile strength, allowing them to withstand significant forces without breaking.

- Corrosion Resistant: Metal alloys are often corrosion-resistant, making them ideal for use in harsh environments.

Examples of metal alloys used in air conditioner parts include:

- Steel

- Cast Iron

- Titanium

- Tungsten

Composites

- High-Performance: Composites offer high-performance characteristics, such as strength, stiffness, and lightness.

- Flexibility: Composites are flexible and can be molded into complex shapes, making them suitable for various applications.

- Corrosion Resistant: Composites are corrosion-resistant, making them ideal for use in harsh environments.

Examples of composite materials used in air conditioner parts include:

- Carbon-Fiber

- Fiberglass

- Kevlar

Maintenance And Troubleshooting Of Air Conditioner Parts

Regular maintenance and troubleshooting are crucial for ensuring the proper functioning and longevity of air conditioners. These tasks include:

General Maintenance

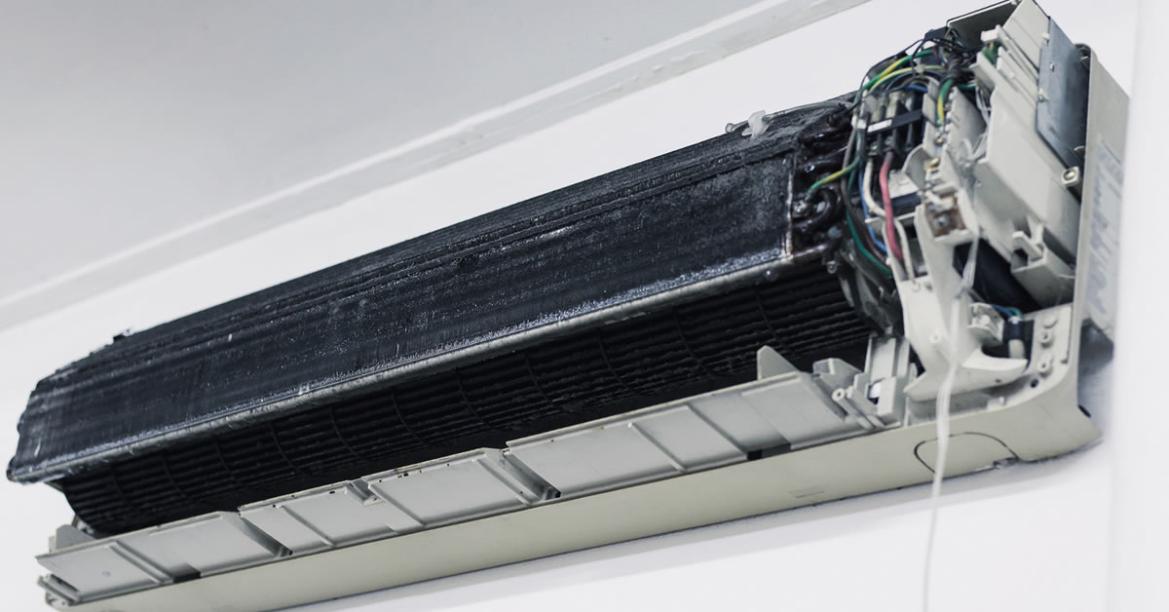

- Periodic Inspection and Cleaning: Regularly inspecting and cleaning air conditioner parts can help prevent problems and extend their lifespan.

- Lubrication of Moving Parts: Moving parts, such as bearings and gears, should be lubricated regularly to reduce friction and wear.

- Tightening of Loose Fasteners: Loose fasteners can cause vibrations and noise, so they should be tightened periodically.

Troubleshooting Air Conditioner Parts

Common issues with air conditioner parts and their symptoms include:

- Air Compressor:

- Excessive Noise: Excessive noise from the air compressor may indicate worn bearings or a faulty piston.

- Low Air Pressure: Low air pressure may be caused by a refrigerant leak, a clogged filter, or a faulty compressor.

- Air Filter:

- Clogging: A clogged air filter can restrict airflow and reduce cooling efficiency.

- Torn Filter Media: Torn filter media can allow dirt and debris to enter the system, causing damage to other components.

- Air Regulator:

- Faulty Pressure Gauge: A faulty pressure gauge may provide inaccurate readings, leading to improper system operation.

- Leakage: Leakage in the air regulator can cause a loss of refrigerant and reduced cooling performance.

- Air Motor:

- Poor Performance: Poor performance of the air motor may be caused by worn bearings, a faulty solenoid, or a clogged air inlet.

- Faulty Solenoid: A faulty solenoid may prevent the air motor from operating properly.

Safety Precautions

- Wear Protective Gear: When handling air conditioner parts, it is important to wear protective gear, such as gloves and safety glasses, to prevent injury.

- Handle Refrigerant Safely: Refrigerant is a hazardous substance, so it should be handled and disposed of properly.

- Follow Manufacturer's Instructions: Always follow the manufacturer's instructions when servicing or repairing air conditioners.

Air conditioners are essential components of modern aircraft, providing a comfortable and controlled environment for pilots and passengers. Understanding the various parts of air conditioners, their functions, and the importance of proper maintenance and troubleshooting is crucial for ensuring the efficient and reliable operation of these systems. By following the guidelines outlined in this comprehensive guide, pilots can ensure the longevity and effectiveness of their air conditioners, contributing to a safe and enjoyable flying experience.

YesNo

Leave a Reply